Pinewood Derby Car Assembly

- Turbo Derby

- Aug 17, 2023

- 4 min read

Updated: Sep 8, 2023

Once your wheels, axles, and car body are completed, it’s time for Pinewood Derby® car assembly!

Determine your desired weight balance/distribution (see Weighting article). Next, attach the wheels and axles to the car; however, do not insert the axles all the way.

PRO RACER TIP FROM Reece Racing: Use a second or spare set of wheels and axles to work out your weight distribution. This keeps accidental damage to the actual race wheels/axles to a minimum. Also, the axle holes/slots may need to be relaxed a bit and a spare axle is a good choice for this.

Arrange the weight on the car in the approximate final location (easiest to do with a flat/thin car). Place the car on your preferred balance tool (scales or straight edge). Shift the weight until you hit your desired weight distribution/balance point. Affix the weights using two-sided tape or glue. Cover over the weight with foil tape. Cover all holes and pockets in the car that could trap air, slowing it down. Cavities can be covered using packing tape, vinyl, or another similar material.

Insert the wheels and axles all the way. For rail riding setups, you will want the right front axle head of the bent axle to point downward.

Setting the Wheel Gaps

When inserting the wheels into the body, you want a small gap between the wheel’s inner hub and the body itself. Too much gap and the wheels will move back and forth on the axles, causing the car to wiggle and lose speed. Too little space and the wheel will bind against the body. Set your gap so there is enough room for the wheel to move back and forth slightly on the axle. Four sheets of standard copy paper can be used for setting the gap. Insert the paper between the car body and the inner wheel hub, push the wheel/axle into the body until tight, then remove the paper. Alternatively, a gap tool used by league racers is available here. League racers like small wheel gaps of 0.01 inches or so.

Raised Front Wheel

The wheels are a significant source of potential energy drain on a Pinewood Derby® car. Raising the non-steer wheel (typically the front left) so it does not contact the track reduces the amount of energy used to start the wheels spinning.

There are different methods to raise the front wheel:

The bending of the front steer axle and the tilting of the steering wheel are often enough to lift the non-steer wheel off the track. This is the preferred method for league racers.

The non-steer wheel axle hole can be drilled slightly higher than the steer wheel axle hole. This is a good option for Race Teams. The standard (smaller) version of the Turbo Jig has the non-steer front hole set 0.01” higher.

If bending axles is not prohibited, then the raised wheel axle can be bent and rotated, so the wheel does not contact the track.

When installing the raised wheel, push the axle in tight so the wheel is pinned against the car body. You do not want to risk the wheel spinning, creating vibrations.

Tuning/setting steer

You’ll need to adjust your steer if running a rail rider setup. To do so, you will need a way to measure how much the car steers over a given distance. Any flat surface that is 5-6 feet long and can be slightly elevated at one end and leveled side to side will work. A board, shelving, coffee table, a full-length mirror, etc., are good options to use as a tuning board.

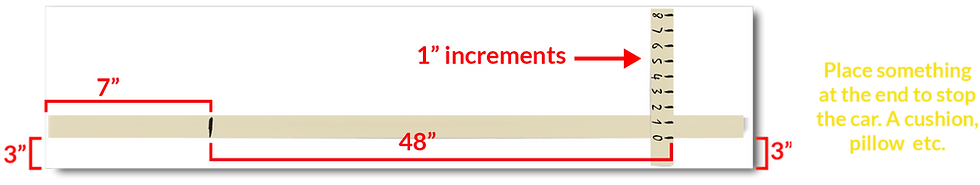

Measure two to three inches from the side at both ends (see graphic below). Put a piece of tape running down the board so it is straight and parallel to the sides. The tape running down the board is your center line. Next, measure 55 inches (48 inches plus 7 inches for the car) from one of the ends and put a piece of tape across the width of the board. Mark the second piece of tape in increments of one inch starting from the longer strip of tape.

Place the board on a flat surface and slightly elevate the start end. You want just enough slope so the car will run down the board slowly but consistently. Check that the board is level side to side and shim as needed to level it. Make sure you have a helper, pillow, blanket, or some way to stop the car when it rolls to the end of the board. Placing your board on the floor helps prevent your new car from rolling off the board and the table!

Place the car at the top of the board, align the outside of the wheels with the tape, and let the car roll down the board.

Using a flathead screwdriver, adjust the steer by turning the axle. Clockwise will turn the car to the right (decreasing steer), and counterclockwise will turn the car to the left (increasing steer). The steer can be very sensitive, so minor adjustments are needed. Make changes until you have the car steering your desired amount. The proper steer amount is usually 4-6 inches.

Setting steer is a balancing act between the amount of steer and the weight on the front wheel. If you have more weight on the front wheel, the car will need less steer; less weight will require more steer.

If you do not have access to a track to tune on, a good car setup would be 16-17 grams (0.56-0.60 oz) on the front wheel and 4-5 inches of steer!

PRO RACER TIP FROM DWS Racing: It’s FAR BETTER to have a little more steer than you think you need than to have too little that results in an unstable car!

Articles in this series (click to read):

Comments